Decorative and industrial paint on demand

From empty cans to finished goods

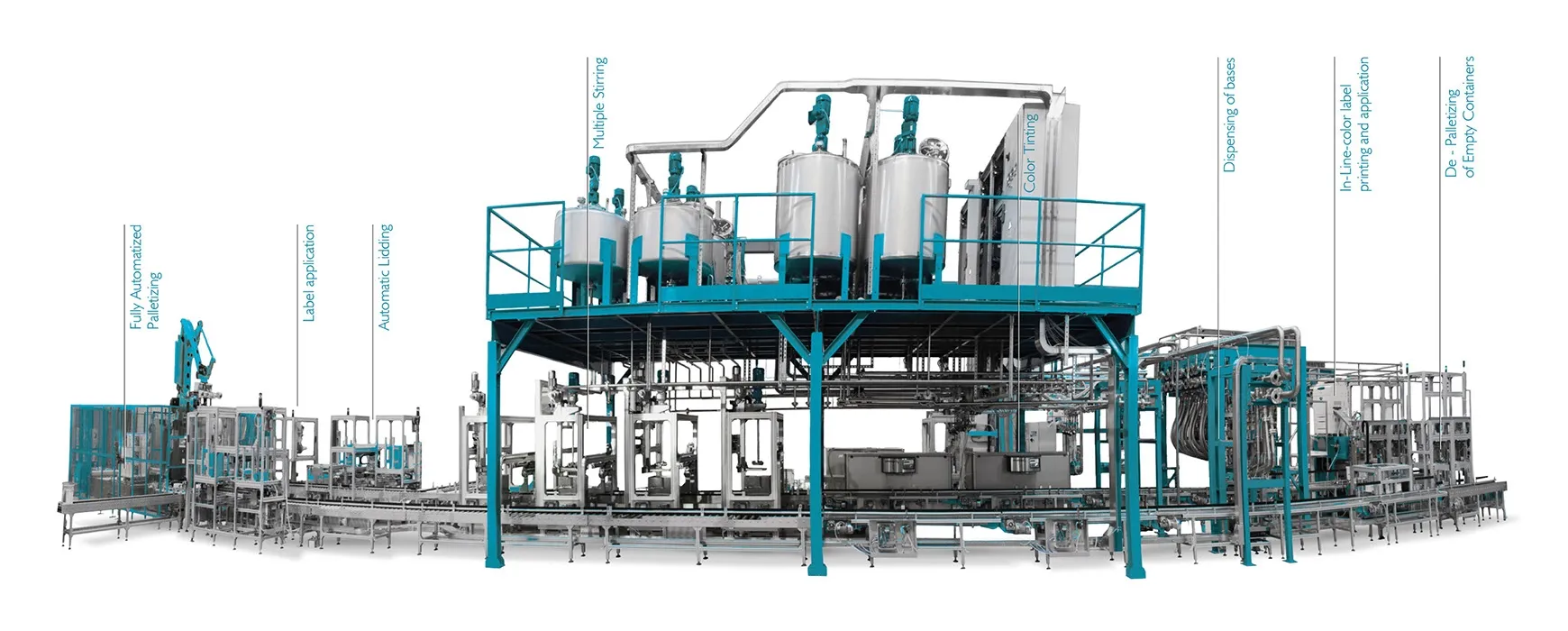

Dromont designs and manufactures fully automatic in can lines to dose all the components into empty or pre-filled cans and pails that functions as final shipping containers. This technology integrates complete handling lines including labeling, agitation and palletizing.

This solution allows for rapid, low-waste and low-cost manufacturing of custom products without the need to carry finished goods inventory. You can therefore increase profitability by shortening delivery times and reducing warehouse space, inventory and working capital.

Dromont provides turnkey integrated lines as well as all ancillary equipment including denesting, label printing and application, automatic lidding, robotic multiple mixing stations, palletizer and the related software and hardware complete control system.

This department is capable of customizing the interface software to the customer’s exact needs, testing the software prior to installation, and programming the software to communicate with the customer’s systems. By using the very stable base platform of the Dromont software, Dromont’s engineers are able to then create many different options that will allow the customer to manage the entire plant.

Plant Software & Automation provides the user with a brand-new experience, by merging HMI, SCADA and MES into a single solution. The innovative architecture allows an unbelievable server-centric organization, capable of coordinating and connecting several clients, even on the web and with mobile devices.