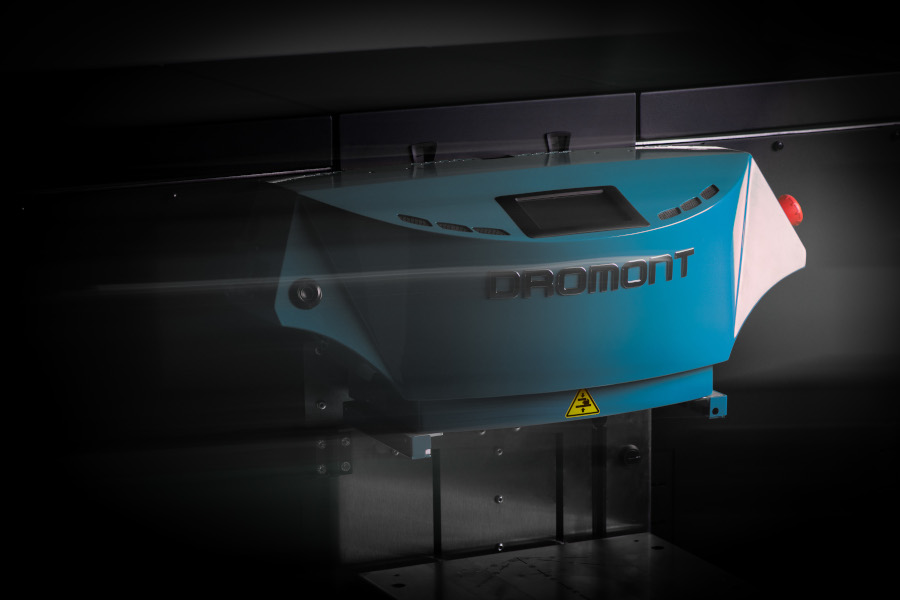

The ultimate tinting machine for professional paint stores

Perfecta meets our customers’ needs to avoid mistints and color contamination, facilitate cleaning and address issues related to VOC Free Colorants.

We have taken our factory dispensing experience and applied it to the retail market. Perfecta represents another huge step forward, guaranteeing the lowest total cost of ownership and environmental sustainability.

Main advantages

- No more daily purging and maintenance: Thanks to the patented solution systems daily maintenance becomes weekly maintenance, resulting in colorant and labor savings of over 3,000 €/$ per year.

- Self-humidification system (as optional): Thanks to the patented Self-humidification system, the machine self-maintains an optimal humidification level of the cap. No need for ordinary maintenance (dosing head cleaning, sponge humidification or replacement)

- Enhanced Performance feedback via Remote monitoring of your stores: Dispensers connected in ‘real time’ providing optimization of the colorant inventory, improved marketing insight by colorant and the ability to remotely diagnose most dispenser service needs.

- Automatic Logging of Colorant Levels and Alarm: with Dromont’s unique Canisters Level Sensor (as optional), you can visualize the true level of each colorant, avoid empty canisters that result in the suction of air in the circuit plus you will no longer need to log colorant additions as the Dromont software will automatically register the new colorant volumes.

- Extend Colorant Life and Quality: You can program the best agitation frequency per each canister and visualize that each agitator is working properly.

- Avoid Colorant Messes & Damage due to Overfilling of Canisters: Dromont canister over-fill prevention kits avoid the mess created with an overfilling of a colorant canister as well as protect the agitator motor from damage.

- Mini-PC embedded in the machine (as optional): Plug&Play, no hassle at the stores, less money and time and fits inside the dispenser cabinet. Mini-PC is shipped preconfigured.

- Recyclable materials

- Water generator and reduced purge = Low impact on the Environment

- Sustainable Packaging

High-speed with simultaneous tinting

- No issues for VOC Free Colorants due to airtight autocap and self-humidification system

- No color contamination

- No daily cleaning operations

Cost champion

- Lower operator time

- Reduced colorants purging, dramatic waste saving

- Mistints eliminated

- Downtimes eliminated

- Lowest cost of maintenance

- Speed and accuracy

- Single global machine calibration

Technical features

- Flow rate (per circuit): 0.6 Lt./min (*) – 21oz./min

- Accuracy: 1/768th fl.oz. (0,038cc) variable depending on the rheology of the products

- Top back electrical cabinet position

- Air-tight “Patented” Automatic cap that guarantees a hermetic closure of the dosing head and prevents colorants drying out – no more daily purge but once a week

- “Patented” Self-humidification system (as optional) that eliminates daily maintenance operation and guarantees an independent humidification of the cap even in a dry environment

- “Patented” Automatic Colorant Level Sensors (as optional) allow to visualize the true level of each colorant, avoid empty canisters and eliminates the possibility of declaring incorrect quantities

- Standard configuration: 16 -24 -32 canisters available in 3, 5, 6 and 10 liters (quarts) capacity. Canisters capacities: 15-25 liters (quarts), available as optional

- Stainless steel piston pumps (easy to be replaced by non-expert operator)

- Simultaneous dispensing: all the colorants dispensed at the same time

- Canisters made of POM polymer material (**) – Stainless steel available as optional

- Each canister has an independent motorized agitator for product homogenization

- Recirculation of colorants avoids sedimentation and air entrapment

- Automatic central shelf, with safety photocell for automatic detection of cans

- Lateral foldable plate shelves treated in Ertalyte to easily handle sample pots and buckets (as optional)

- ABS charcoal grey color external panels (special colors as optional)

- Dispensing head max diameter: 40 mm

- Volumetric and gravimetric dispensing

Point-of-Sale Software

& DromontApp

Dromont In-House Software Department consists of internal programming engineers working on updating our software platform to the latest innovations as well as integrating our machines into the customer’s Enterprise Resource Planning (ERP) system. This department is capable of customizing the software interface to the customer’s exact needs, testing the software prior to installation, and programming the software to communicate with the customer’s systems.

Thanks to the new DromontApp it is also possible to remotely monitor in real time machine status and performances. It allows operators, service technicians and service companies to collect data and show messages for a predictive maintenance support; guiding customers to quickly identify the origin of a downtime and immediately return in operation.

Data collected are mainly calibration data, counters, canisters colorants level, alarms history, configuration settings, dispensing and purges.